Branding

Customer

Cases

We cooperate with well-known domestic and international customers and the quality of all our products is recognized.

Welcome to Environmental Equipment Manufacturers.

Products and services are highly trusted by global users

Yangzhou Qinxin Environmental Protection Technology Co., Ltd. is

More About Us

-

Working Space

0

Square meters

-

Customers

0+

Case

-

Frontline Worker

0+

Workers

-

Honor

0+

The Certificates

-

Technical Staff

0+

Officers

PRODUCT

Customized and Diversified Products

Our company is mainly engaged in stacked screw sludge dewatering machine, PAM integrated dosing device, sludge low-temperature drying system, solid-liquid separator and other sewage treatment equipment...

More About Us

-

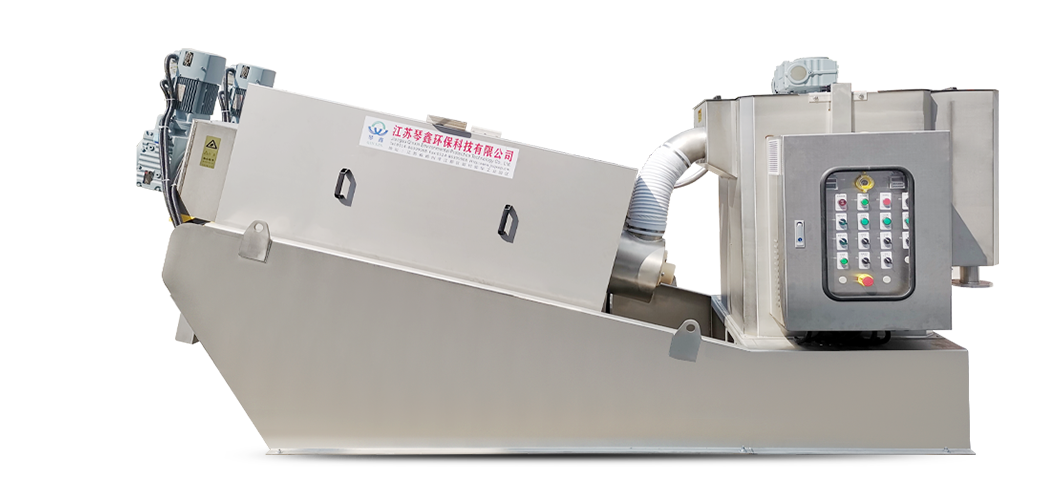

Screw Press Sludge Dewatering Machine

View More

View More

-

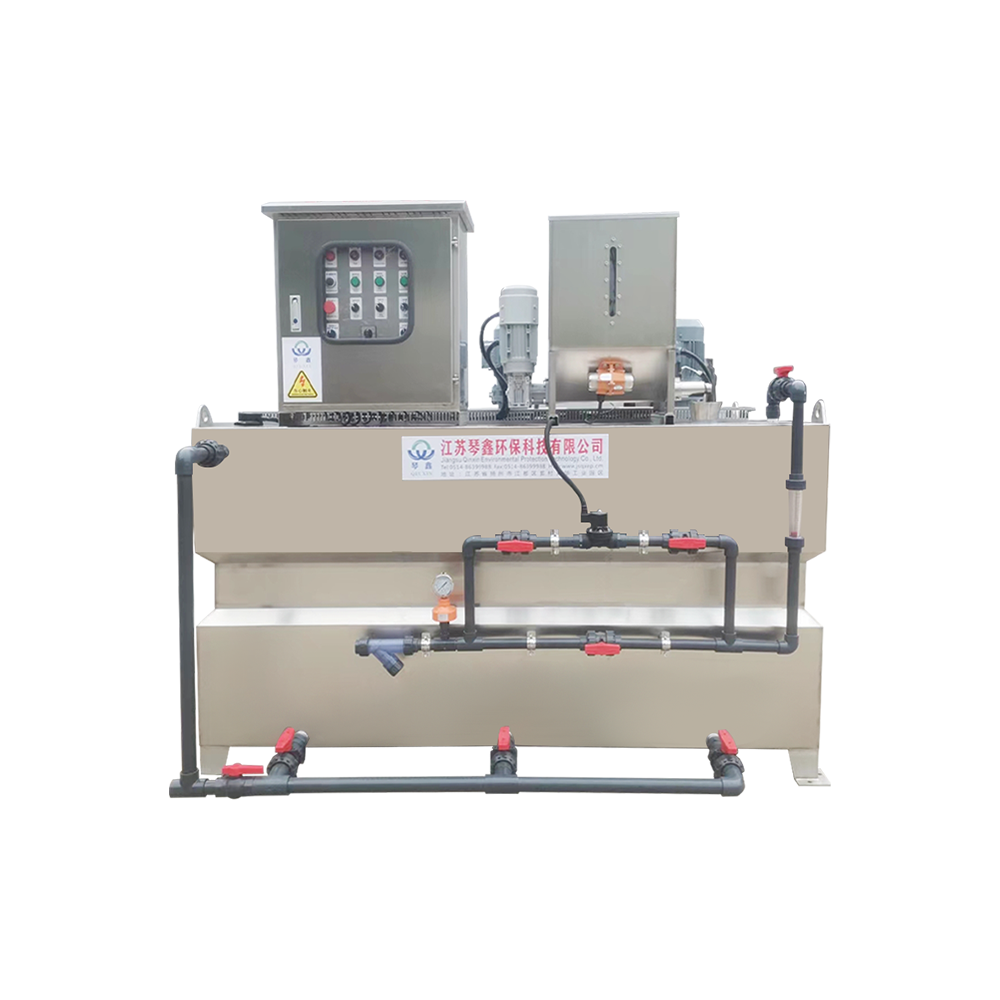

Integrated Frequency-Converting Dosing Device

View More

View More

-

Drum Filter

View More

View More

-

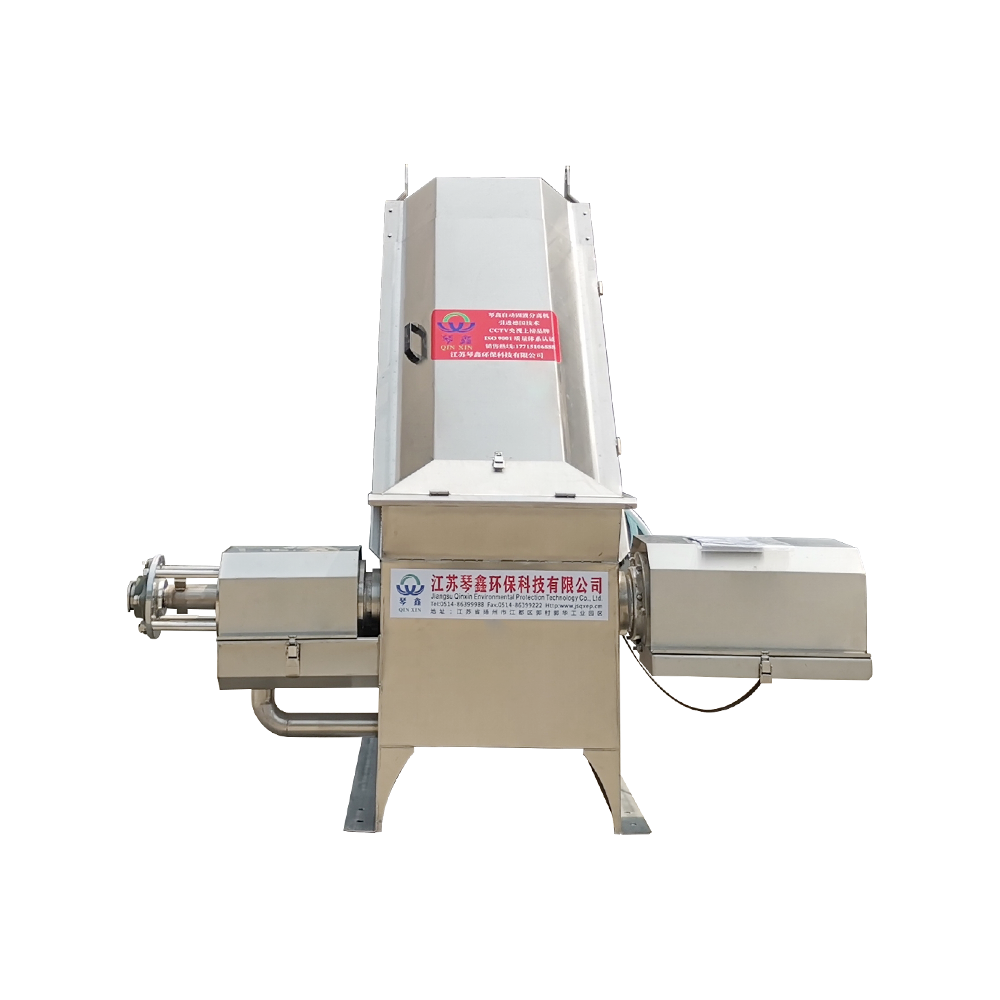

Solid-Liquid Separator

View More

View More

-

Hydraulic Screen Solid-Liquid Separator

View More

View More

-

Microfiltration Solid-Liquid Separator

View More

View More

-

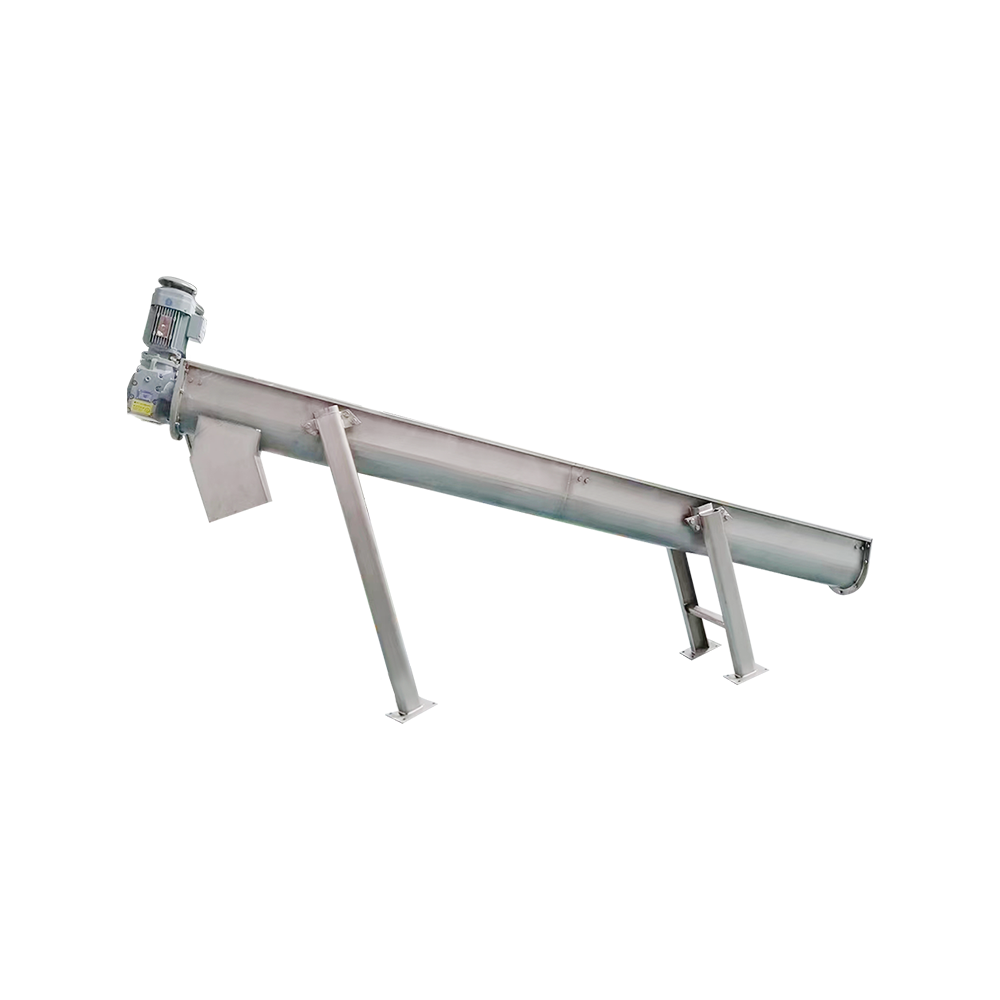

Axleless Screw Conveyor

View More

View More

-

Stainless Steel Lifting Device

View More

View More

Recommended Products

Products provided by famous enterprises are deeply trusted by users.

Food Factory Environmental Protection Equipment

Environmental protection equipment plays a crucial role in food factories, helping to solve problems such as environmental pollution and waste disposal.Wastewater treatment equipment: A large amount of wastewater is generated during food processing, which may contain organic matter, oils, suspended solids, and chemical substances. Wastewater treatment equipment such as sedimentation tanks, biological treatment systems, and membrane separation equipment can be used to remove pollutants, purify wastewater, and meet discharge standards.Waste gas treatment equipment: Food processing may generate waste gases, including smoke, odors, and organic compounds. Waste gas treatment equipment such as dust collectors, adsorption devices, and activated carbon filters can help remove harmful substances and reduce the impact on the environment and employee health.Solid waste treatment equipment: The solid waste generated by food factories, such as packaging materials, waste, and by-products, needs to be properly treated. Recycling and reusing equipment such as compressors, sorting machines, and composting equipment can help reduce waste volume and promote resource recycling.Energy-saving equipment: Food factories can adopt energy-saving equipment and technology to reduce energy consumption and carbon emissions. For example, measures such as installing efficient lighting systems, optimizing production lines, recovering heat, and using renewable energy can effectively reduce energy use and waste.Intelligent monitoring and management system: By establishing an intelligent monitoring and management system, food factories can monitor environmental indicators and energy consumption in real-time, and carry out effective management and regulation. This helps to identify problems, optimize processes, and improve environmental efficiency and sustainability.In addition to the equipment and solutions listed above, specific environmental requirements and situations may vary depending on the scale, process, and types of pollutants in the food factory. Therefore, it is recommended that food factories conduct a comprehensive environmental assessment and compliance check before introducing environmentally friendly equipment to ensure the selection of appropriate equipment and systems to meet environmental requirements and comply with relevant regulations and standards.

View More Details

Animal Husbandry Environmental Protection Equipment

Animal husbandry is an industry that faces environmental challenges, but by adopting appropriate environmental protection equipment and solutions, the impact on the environment can be reduced.Wastewater treatment equipment: Animal husbandry generates a large amount of wastewater, which contains pollutants such as organic matter, ammonia nitrogen, phosphorus, etc. Wastewater treatment equipment such as sedimentation tanks, biological treatment systems, and artificial wetlands can be used to remove pollutants, purify wastewater, and meet discharge standards.Gas processing equipment: Emissions from animal husbandry, such as ammonia, hydrogen sulfide, and methane, have adverse effects on the environment and air quality. Gas processing equipment such as gas filters, gas scrubbers, and biogas reactors can help remove harmful gases and reduce their impact on the surrounding environment and residents.Waste treatment equipment: Animal husbandry generates a large amount of waste, including animal manure, straw, feed residue, etc. Appropriate waste treatment equipment such as biogas fermentation equipment, composting equipment, and biomass combustion equipment can help convert waste into energy or organic fertilizers, reducing the burden on the environment.Intelligent breeding system: Introducing an intelligent breeding system can effectively manage the production process of animal husbandry, and reduce resource waste and environmental pollution. For example, using sensors to monitor feed consumption and animal health status, and controlling automated feeding and ventilation systems to reduce energy consumption and gas emissions.Fecal treatment and utilization: For the large amount of feces produced in animal husbandry, fecal treatment and utilization technologies can be adopted. For example, through treatment processes such as biogasification, biogas fermentation, or anaerobic digestion, feces can be converted into biogas or biomass energy for power generation, heating, or fuel.In addition, animal husbandry should also pay attention to reasonable land use, water resource management, and animal welfare to achieve sustainable development. The situation and needs of each livestock farm may vary, so it is recommended to conduct a comprehensive environmental assessment and feasibility study before introducing environmental protection equipment and solutions to ensure the selection of suitable equipment and systems and compliance with local environmental regulations and standards.

View More Details

Pharmaceutical Factory Environmental Protection Equipment

Pharmaceutical factories are an industry with extremely high environmental protection requirements, as they involve a large amount of chemicals, wastewater, exhaust gas, and solid waste.Wastewater treatment equipment: The wastewater generated by pharmaceutical factories usually contains high concentrations of pollutants such as organic matter, drug residues, and heavy metals. Wastewater treatment equipment such as biological treatment systems, chemical purification devices, and membrane separation equipment can be used to remove pollutants, purify wastewater, and meet discharge standards.Waste gas treatment equipment: Harmful gases, volatile organic compounds, and dust may be generated during the pharmaceutical process. Waste gas treatment equipment such as dust collectors, adsorption devices, and catalytic oxidation equipment can help remove harmful substances and reduce the impact on air quality and employee health.Solid waste treatment equipment: The solid waste generated during the pharmaceutical process includes waste drugs, packaging materials, and laboratory waste. Recycling and processing equipment such as solid waste sorting machines, incinerators, and material recovery systems can help reduce waste volume and achieve resource recycling.Clean energy and energy efficiency improvement: Pharmaceutical factories can adopt clean energy and energy efficiency improvement measures to reduce energy consumption and carbon emissions. For example, measures such as installing efficient lighting systems, optimizing production processes, recovering waste heat, and using renewable energy can effectively reduce energy use and waste.Intelligent monitoring and management system: By establishing an intelligent monitoring and management system, pharmaceutical factories can monitor environmental indicators, wastewater, and exhaust emissions in real-time, and effectively manage and regulate them. This helps to identify problems, optimize processes, and improve environmental efficiency and sustainability.In addition to the equipment and solutions listed above, pharmaceutical factories should also pay attention to drug residue treatment, sterile operations, and waste classification to ensure compliance with strict environmental regulations and standards. Before introducing environmentally friendly equipment and solutions, it is recommended that pharmaceutical factories conduct comprehensive environmental assessments and compliance checks to ensure the selection of appropriate equipment and systems, as well as take appropriate measures to reduce the impact on the environment.

View More Details

Industrial Sludge Environmental Protection Equipment

Industrial sludge is a solid waste generated during industrial production processes that contains a large amount of pollutants.Sludge treatment equipment: Industrial sludge can be reduced in its impact on the environment through different treatment methods. For example, using sludge concentration equipment (such as filter presses, and centrifuges) can remove moisture from sludge and reduce volume. Sludge drying equipment (such as dryers and pyrolysis devices) can decompose and dehydrate organic matter in sludge, reducing its volume and weight. Sludge incineration equipment (such as incinerators and gasifiers) can treat sludge at high temperatures, reducing the content of organic matter and pollutants.Sludge resource utilization: Industrial sludge contains certain organic matter and nutrients, which can be used for resource utilization. For example, using biological composting technology to convert sludge into organic fertilizer can reduce waste and improve soil quality. The metal elements in sludge can also be recovered and reused, such as through processes such as roasting and smelting.Sludge solidification and stabilization: For industrial sludge with a high amount of harmful substances, solidification and stabilization technology can be used to fix harmful substances in the sludge, reducing their release and migration to the environment. Common solidification and stabilization methods include the addition of curing agents, cement solidification, and sintering.Intelligent monitoring and management system: By establishing an intelligent monitoring and management system, key parameters and environmental indicators during sludge treatment can be monitored in real time to ensure compliance with emission standards and regulatory requirements. This helps to promptly identify problems, optimize processing, and improve environmental efficiency and sustainability.When selecting suitable environmental protection equipment and solutions, it is necessary to consider factors such as the characteristics of industrial sludge, pollutant composition, treatment scale, and regulatory requirements. It is recommended to conduct a comprehensive analysis of sludge characteristics and assessment of treatment needs to ensure the selection of appropriate equipment and technology while complying with relevant environmental regulations and standards.

View More Details

Chemical Industry Environmental Protection Equipment

The chemical industry is an industry that faces challenges in environmental protection, but by adopting appropriate environmental protection equipment and solutions, the impact on the environment can be reduced.Wastewater treatment equipment: The chemical industry produces a large amount of wastewater, which contains pollutants such as organic matter, heavy metals, and toxic substances. Wastewater treatment equipment such as biological treatment systems, chemical purification devices, and membrane separation equipment can be used to remove pollutants, purify wastewater, and meet discharge standards.Waste gas treatment equipment: The waste gas generated during the chemical process contains volatile organic compounds, gas pollutants, and particulate matter. Waste gas treatment equipment such as dust collectors, adsorption devices, and catalytic oxidation equipment can help remove harmful substances and reduce the impact on air quality and employee health.Solid waste treatment equipment: The solid waste generated by the chemical industry includes waste, waste liquid, waste residue, etc. Appropriate solid waste treatment equipment such as solid waste sorting machines, incinerators, and material recovery systems can help reduce waste volume and achieve resource recycling.Clean production technology: Introducing clean production technology can reduce the generation of waste and pollutants in chemical processes. For example, measures such as optimizing reaction conditions, improving catalysts, using green solvents, and replacing harmful substances can reduce waste generation and environmental pollution.Energy management and energy efficiency improvement: The chemical industry usually consumes a large amount of energy, so adopting energy management and energy efficiency improvement measures is crucial for environmental protection. For example, measures such as optimizing the energy supply chain, improving equipment energy efficiency, recovering waste heat, and using renewable energy can reduce energy consumption and carbon emissions.Risk management and emergency response: The chemical industry involves some hazardous materials and environmental risks, so it is crucial to establish a sound risk management and emergency response mechanism. This includes developing emergency plans, establishing monitoring systems, conducting risk assessments, and training employees.In addition to the equipment and solutions listed above, the chemical industry should also focus on product design, green chemical use, and circular economy to achieve sustainable development. The situation and needs of each chemical enterprise may vary. Therefore, before introducing environmental protection equipment and solutions, it is recommended to conduct a comprehensive environmental assessment and feasibility study to ensure the selection of suitable equipment and systems and compliance with local environmental regulations and standards.

View More Details

Municipal Sludge Environmental Protection Equipment

Municipal sludge is solid waste generated by urban sewage treatment plants after treating sewage, which contains organic matter, nutrients, and microorganisms.Sludge concentration and dewatering equipment: Municipal sludge usually has a high moisture content, so it needs to be concentrated and dehydrated for treatment. Commonly used equipment includes filter presses, centrifuges, and belt dehydrators, which can reduce the moisture content of sludge and reduce the volume and weight of waste.Sludge drying equipment: Drying is the process of evaporating water from sludge, thereby reducing its volume and weight. Common drying equipment includes dryers and pyrolysis devices, which evaporate the moisture in sludge through the action of thermal energy and can decompose organic matter.Sludge incineration and gasification equipment: Incineration and gasification are methods of high-temperature treatment of sludge, which can effectively reduce the content of organic matter and reduce the volume of waste. Incineration equipment such as incinerators and fluidized bed burners can burn sludge into ash and flue gas, while gasification equipment can convert sludge into renewable energy, such as syngas or liquid fuels.Sludge solidification and stabilization: For municipal sludge containing harmful substances, solidification and stabilization technology can be used to fix harmful substances in the sludge, reducing their release and migration to the environment. Common solidification and stabilization methods include the addition of curing agents, cement solidification, and sintering.Sludge resource utilization: Municipal sludge contains organic matter and nutrients, which can be used for resource utilization. For example, using biological composting technology to convert sludge into organic fertilizer can reduce waste and improve soil quality. The metal elements in sludge can also be recovered and reused.Intelligent monitoring and management system: By establishing an intelligent monitoring and management system, key parameters and environmental indicators during sludge treatment can be monitored in real time to ensure compliance with emission standards and regulatory requirements. This helps to promptly identify problems, optimize processing, and improve environmental efficiency and sustainability.When selecting suitable environmental protection equipment and solutions, it is necessary to consider factors such as the characteristics of municipal sludge, treatment scale, and regulatory requirements. It is recommended to conduct a comprehensive analysis of sludge characteristics and assessment of treatment needs to ensure the selection of appropriate equipment and technology and to comply with local environmental regulations and standards. At the same time, economic feasibility and social acceptance should also be considered to achieve sustainable municipal sludge management.

View More Details

Latest News and Events

Share with you

View More News

Share with you

-

29 Jan,2026

29 Jan,2026What are the Key Factors Affecting the Energy Efficiency of a screw dewatering machine?

In the evolving landscape of global wastewater management, energy optimization has transitioned from... -

22 Jan,2026

22 Jan,2026What is the Optimal Sludge Concentration for a Sludge Dewatering Screw Press to Achieve Maximum Cake Dryness?

In the field of industrial and municipal wastewater treatment, achieving the highest possible solids... -

16 Jan,2026

16 Jan,2026How a Screw-Press solid liquid separator machine Reduces Waste Management Costs on Large-Scale Dairy Farms

In the intensive dairy industry, waste management is no longer merely an environmental obligation bu... -

08 Jan,2026

08 Jan,2026How Does a Screw Dewatering Machine Achieve Higher Cake Dryness Compared to a Belt Press?

In the evolving landscape of industrial wastewater management, the efficiency of sludge thickening a... -

01 Jan,2026

01 Jan,2026How Does a Sludge Dewatering Screw Press Reduce Operational Costs Compared to Belt Filter Presses?

In the evolving landscape of wastewater management, industrial and municipal operators are increasin... -

25 Dec,2025

25 Dec,2025Stainless Steel Selection for screw sludge dewatering machine in Highly Corrosive Sludge Treatment

Corrosion Characteristics of High-Corrosion Industrial Sludge High-corrosion industrial sludge commo...

TOP

TOP

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย