The main challenge that paper companies face when treating pulping wastewater is that the sludge contains high fiber, organic matter and moisture. Traditional treatment methods are difficult to efficiently separate solids and liquids, and can easily lead to resource waste and high discharge costs. The introduction of efficient sludge dewatering equipment (such as environmentally friendly spiral sludge dehydrator) can optimize the treatment process, reduce waste discharge and recover water resources from the following aspects:

1. Efficient solid-liquid separation to reduce waste emissions

Optimize dehydration effect: The spiral dehydration equipment can quickly separate high fiber and solid particles in the sludge through a tapered spiral extrusion and filtration system, and reduce the sludge moisture content to 50%-60%.

Reduce sludge volume: The volume of high-fiber sludge is significantly reduced after dehydration, reducing transportation and final disposal costs.

Reduce landfill pressure: Dried sludge can reduce dependence on landfills and avoid environmental pollution.

2. Recycle fiber resources

High fiber recovery: The equipment can effectively capture the fiber components in the sludge. These fibers can be further processed as papermaking raw materials to improve resource utilization.

Reduce raw material consumption: Through fiber recycling, the demand for wood pulp or recycled pulp is reduced, thereby reducing corporate production costs.

3. Improve wastewater recycling rate

Separating clean water: The liquid separated by the dehydration equipment has a high degree of cleanliness and can be reused in non-production links (such as equipment cleaning and factory greening) after simple treatment, reducing the consumption of new water.

Reduce the pressure on discharge standards: Through equipment pretreatment, the suspended solids (SS), chemical oxygen demand (COD) and biological oxygen demand (BOD) in the wastewater are significantly reduced, which reduces the burden on subsequent biochemical treatment and ensures that discharge standards are met.

4. Save energy and reduce consumption to achieve environmental benefits

Low energy consumption operation: The spiral dehydration equipment adopts a low-speed design, which consumes less energy than traditional centrifugal dehydration equipment and is in line with the concept of green production.

Reduce the use of chemicals: Efficient solid-liquid separation can be achieved without or in small amounts using flocculants, reducing reliance on chemical treatments and reducing secondary pollution.

5. Meet the requirements of sustainable development

Support the circular economy: Promote waste “recycling” and reduce waste generation through fiber recycling and water reuse.

Meet environmental regulations: The equipment helps companies control pollutant emission levels, meet strict national and regional requirements for sewage and waste treatment, and reduce the risk of environmental penalties.

Improve corporate image: Green processing technology meets consumers and society's expectations for environmentally friendly companies and helps enhance brand competitiveness.

Cases and suggestions

Some advanced paper mills have achieved a sludge reduction of more than 70% by introducing high-efficiency spiral dehydration equipment, while recycling hundreds of tons of fiber resources and thousands of tons of industrial water every year.

It is recommended that papermaking enterprises select an appropriate spiral sludge dehydrator model based on the characteristics of sewage, and match it with subsequent sewage treatment processes (such as membrane filtration or biochemical treatment) to form a complete sludge and wastewater closed-loop management system.

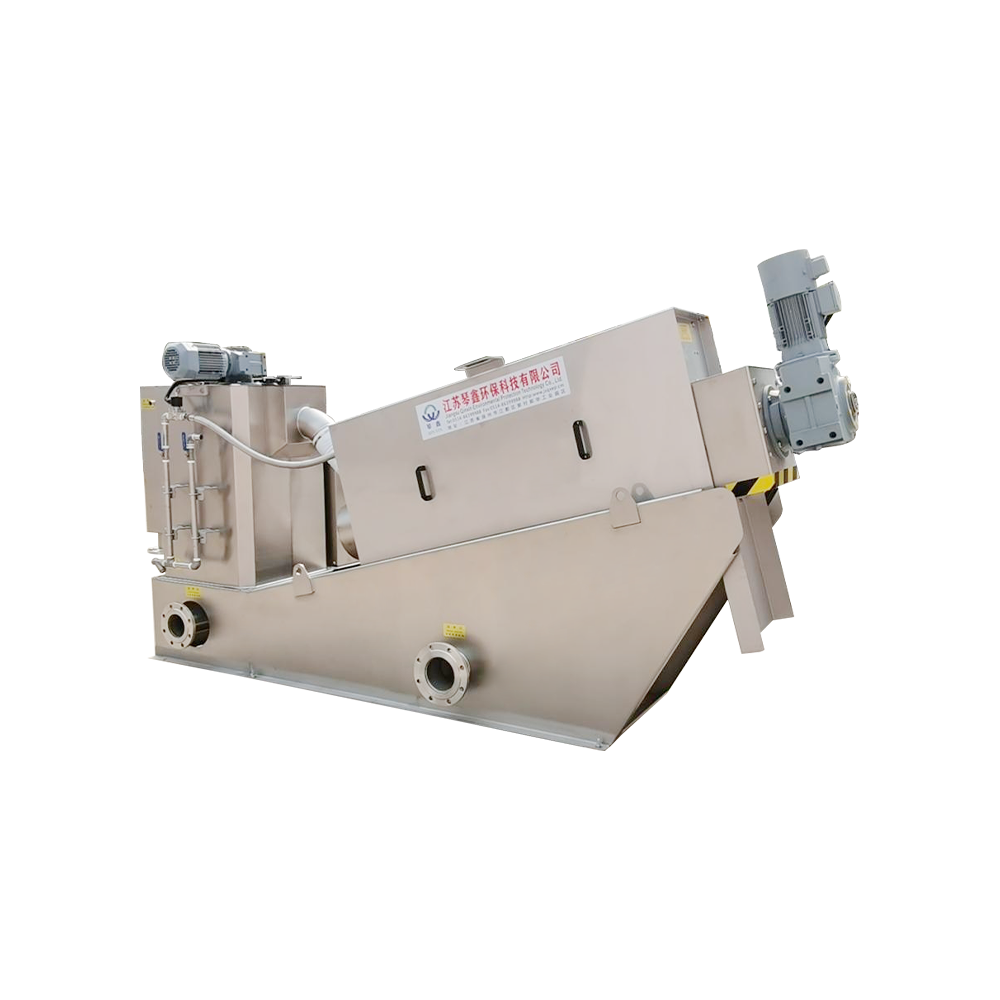

Eco-friendly Solid-Liquid Separation Spiral Screw Sludge Dewatering Machine QXDL-301

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP