In the highly sophisticated and demanding pharmaceutical industry, every production link is directly related to the quality and safety of the final product. From the screening of raw materials to the packaging of finished products, each step must be strictly controlled and tested. In this long production chain, the drum filter has become an indispensable and important equipment in the pharmaceutical process with its unique advantages.

1. Special needs of the pharmaceutical industry

The pharmaceutical industry has almost stringent requirements for the purity and safety of products. Whether it is APIs, intermediates, or fine chemicals and biological products, it is necessary to ensure that impurities and microorganisms are removed to the maximum extent during the production process to prevent these harmful substances from posing a potential threat to human health. Therefore, it is crucial for pharmaceutical companies to choose an efficient and reliable filtration equipment.

2. The unique advantages of drum filters

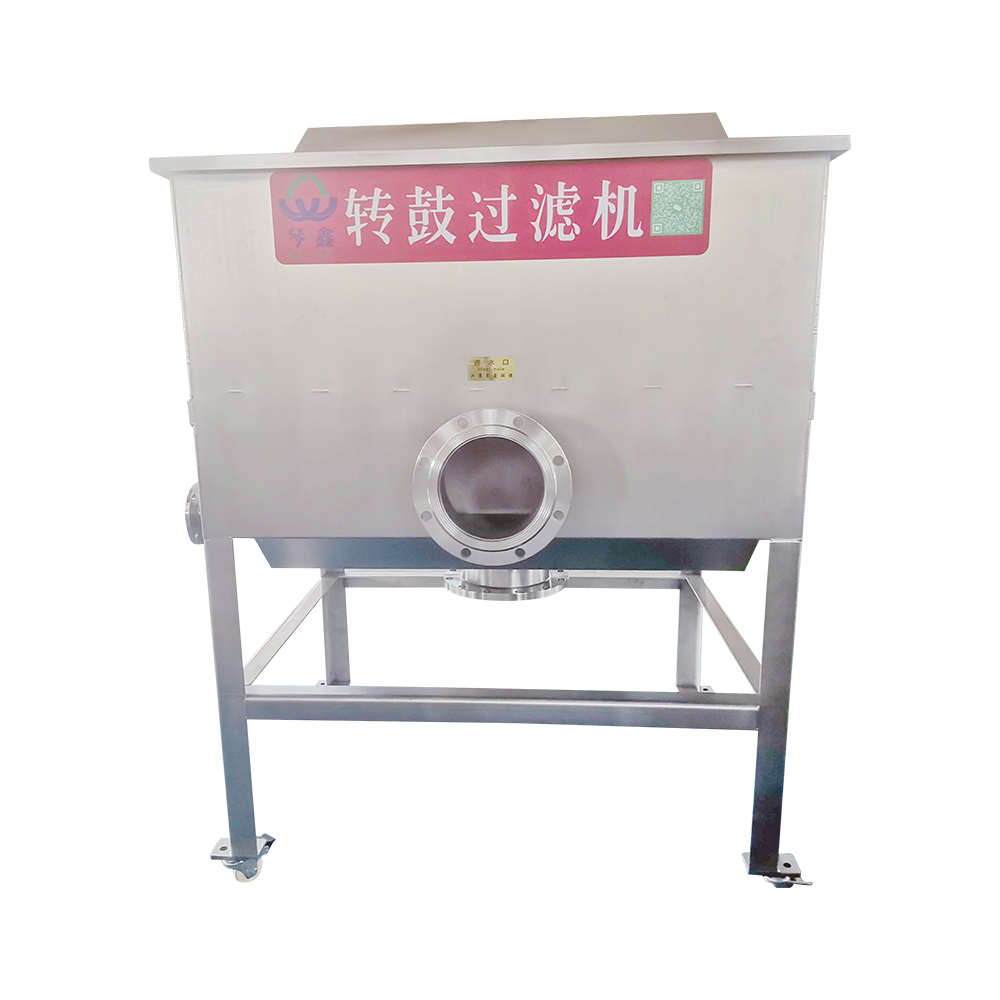

The drum filter stands out in the pharmaceutical industry for its efficient filtration capabilities. It adopts the principle of physical separation, and effectively separates impurities such as particles and microorganisms in raw materials or solutions through the rotation of the drum and the filtering action of the screen. This filtration method is not only efficient, but also ensures the consistency of the filtration effect, meeting the strict requirements of the pharmaceutical industry for product purity.

In addition, the drum filter also has the advantages of corrosion resistance, high temperature resistance, and easy cleaning. These characteristics enable it to operate stably in various complex pharmaceutical environments, extend the service life of the equipment, and reduce the maintenance cost of the enterprise. At the same time, its reasonable structural design and easy operation also greatly improve production efficiency.

3. Application of drum filters in the pharmaceutical process

In the pharmaceutical process, drum filters are widely used in multiple links. First, in the raw material pretreatment stage, it can be used to remove large particle impurities and microorganisms in the raw materials, laying a good foundation for the subsequent production process. Secondly, in the pharmaceutical reaction and extraction process, the drum filter can be used to separate and purify the reaction products to improve the purity and yield of the product. Finally, before the preparation and filling of the preparation, it can also be used for filtration and sterilization to ensure the safety and stability of the final product.

The drum filter plays a pivotal role in the pharmaceutical industry. With its advantages of high efficiency, reliability, and easy maintenance, it provides strong technical support and guarantee for pharmaceutical companies. With the continuous development and progress of the pharmaceutical industry, the drum filter will continue to play its unique advantages and create more value for pharmaceutical companies. At the same time, we also look forward to more innovative technologies and equipment emerging in the future to jointly promote the sustained and healthy development of the pharmaceutical industry.

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP