A dewatering screw press is a mechanical device used for solid-liquid separation. It is widely used in environmental protection, food processing, pharmaceuticals and chemical industries, and is particularly suitable for sludge treatment, fruit and vegetable waste dehydration and food waste treatment. Its high efficiency and energy-saving characteristics make it the best choice for treating high-humidity materials.

Working principle

The dewatering screw press drives the material along the filter screen through the rotation of the screw shaft. The pitch and diameter of the screw shaft gradually decrease, so that the material is subjected to a gradually increasing extrusion force during the movement. The liquid in the material is discharged through the filter screen or filter plate under pressure, and the compressed solid is discharged from the discharge port. The equipment is usually equipped with a tail back pressure device (such as a spring baffle) to adjust the discharge pressure, thereby improving the dehydration efficiency.

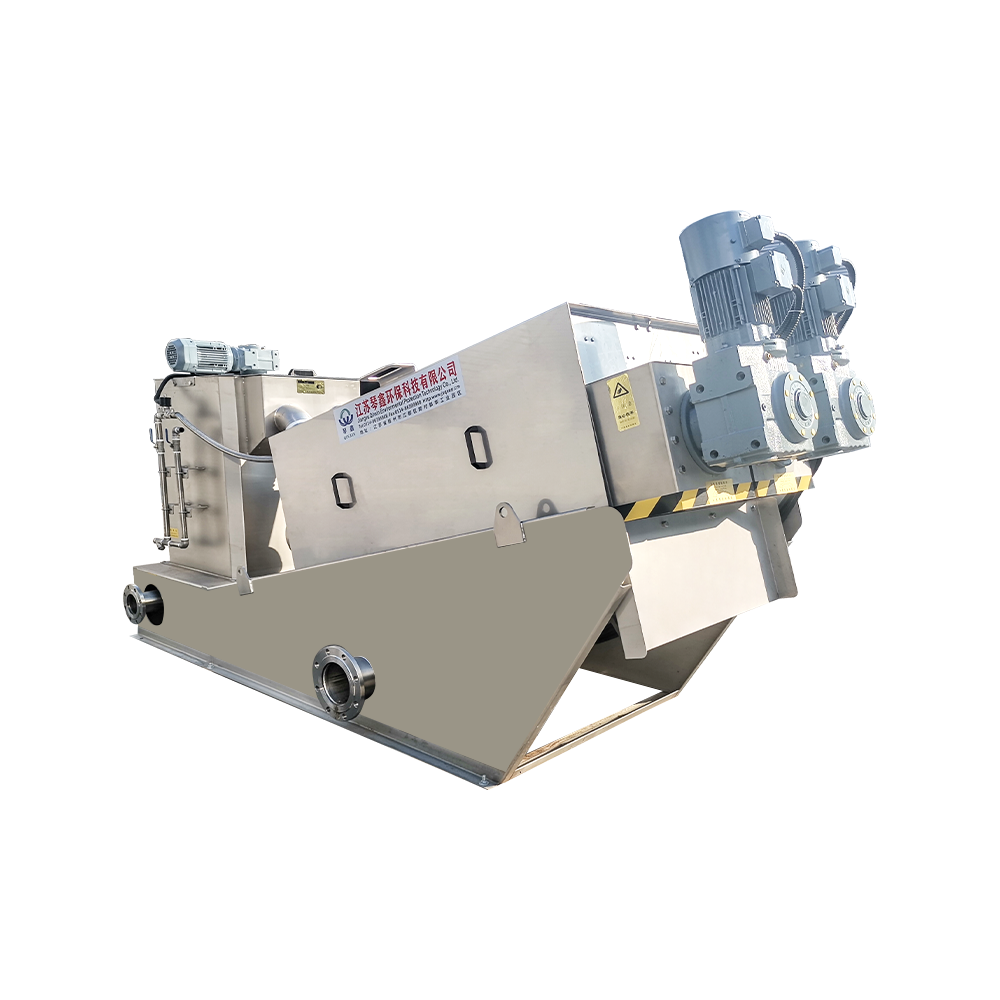

Main structure

The equipment consists of a screw shaft, a filter device, a drive system, a housing and a drainage device. The screw shaft is responsible for conveying and compressing the material, the filter screen discharges the liquid, the drive system provides rotational power, and the frame and housing ensure stable operation of the equipment. The overall design is simple and easy to clean and maintain.

Working characteristics

Efficient dehydration: Screw extrusion can quickly and effectively separate solids and liquids, significantly reducing the moisture content of materials.

Continuous operation: Materials can be continuously fed in and out, suitable for large-scale processing needs.

Strong adaptability: Can process a variety of materials such as sludge, fruit and vegetable waste, restaurant waste, livestock and poultry manure, etc.

Compact structure: Small footprint, low energy consumption, low operating cost.

Application areas

Environmental protection industry: Used for sludge dehydration and reduction in sewage treatment plants.

Food processing: Juice squeezing, bean dregs dehydration, and residue treatment after tea extraction.

Organic waste treatment: Dehydration of restaurant waste and livestock and poultry manure for subsequent composting or energy utilization.

Industrial waste treatment: Solid-liquid separation of chemical waste liquid, drug residue treatment, etc.

The dehydration screw press has the advantages of simple structure, easy operation, strong corrosion resistance and long service life. It is an important equipment for solid-liquid separation and resource utilization. By adjusting the spiral parameters and back pressure device, accurate dehydration of different materials can be achieved.

Multi-disk Double Worm Gear Eco-friendly Spiral Screw Sludge Dewatering Machine QXDL-302

ENG

ENG

English

English русский

русский Español

Español Tiếng Việt

Tiếng Việt ไทย

ไทย

TOP

TOP